The ENGIMMONIA project (www.engimmonia.eu) is a cutting-edge initiative aimed at addressing one of the most pressing environmental challenges: the decarbonization of the shipping sector.

The project focuses on the use of ammonia as a fuel in marine engines, which has the potential to significantly reduce greenhouse gas emissions.

In addition, ENGIMMONIA is integrating several low-carbon technologies on board ships, including an absorption chiller, photovoltaic panels, an Organic Rankine Cycle system for waste heat recovery, and an Energy Management System to optimize energy use.

Together, these innovations represent a comprehensive approach to reducing the carbon footprint of the maritime transport industry, and advancing sustainable shipping practices.

To achieve our vision for a sustainable maritime future, ENGIMMONIA is focusing on three key objectives and strategies:

First, it is important to study and confirm how ammonia could potentially become a safe and green fuel. This means having not only a clearer picture of its technical behavior, but also an idea of the implementation challenges in new vessels, or on existing ones by retrofit.

The second strategy is to leverage low-carbon technologies which are already proven to work onshore but still require some technical adjustments for usage on board.

As the energy transition transforms industrial processes, infrastructures and technologies, it will also redefine the roles of those who operate, maintain and manage them. Up-skilling and re-skilling will be critical enablers of decarbonization.

At RINA, we are developing a new generation of learning models designed to accelerate workforce readiness, with competence certification at their core.

As part of our global strategy, RINA is establishing a network of seven Open Innovation Hubs in regions with high growth potential - the Middle East, Latin America, the USA, Europe, and Asia. All seven hubs will be fully operational within the next two years. These hubs are designed to be centers of applied innovation and talent development, using training programs that are closely aligned with specific industrial ecosystems.

In Singapore, our first Open Innovation Hub is focused on the green transition of the maritime sector. We are deploying this model to address skills gaps in alternative fuels (such LNG, but also ammonia and methanol), electrification of port systems, and energy efficiency technologies onboard and ashore. These programs are targeted at the backbone of decarbonization efforts: engineers, ships’ crew, yard operators, maintenance technicians, and energy system integrators.

Similar needs are emerging across other hard-to-abate sectors. Whether it’s mastering carbon capture systems in industrial sites, implementing hydrogen-ready infrastructure, or integrating digital monitoring tools for predictive maintenance, workers must navigate new safety protocols, operational standards, and multidisciplinary workflows.

The global energy transition and the EU’s commitment to decarbonization are compelling companies to rethink their business models. Bioenergy is pivotal in this transition. In particular, under the EU Renewable Energy Directive (RED), oil companies can embrace a green model that connects agriculture and energy by producing sustainable biofuels from vegetable oils.

The agro-energy model focuses on converting locally sourced agricultural raw materials - those not competing with food production - and agro-industrial waste into oils and by-products.

This approach enables oil companies to produce significant quantities of vegetable oil for biofuels sustainably, promoting territorial regeneration, job creation, and market access for local communities.

Among the potential feedstocks, rubber tree fruits containing seeds are a notable residue from latex production. The oil extracted from these seeds can be suitable for advanced biofuels, defined by the EU RED as biofuels derived from waste, agricultural residues, or non-food crops, and which do not compete with food or feed crops.

RINA contributed to a study aiming to analyze the production chain of rubber tree seeds, classifying them within the EU RED framework, especially Annex IX, which identifies eligible feedstocks for advanced biofuel production.

Rubber tree cultivation spans over ten million hectares globally, primarily in tropical Asia, and involves mainly smallholders, significantly contributing to rural economies and poverty alleviation.

There is no silver bullet for the global energy transition. Achieving net zero will require a diverse mix of solutions, each tailored to the unique challenges of different sectors and geographies.

Among these, synthetic fuels are emerging as a key enabler for decarbonizing the so-called hard-to-abate segments of mobility, where direct electrification remains technically or economically out of reach.

Heavy-duty transport, maritime shipping, and aviation all depend on high-energy-density fuels to operate efficiently across long distances. Phasing out conventional fossil fuels in these sectors is essential for meeting global climate goals.

This is where synthetic fuels, or e-fuels, come into play.

Produced through chemical synthesis of low-carbon hydrogen and captured CO₂ (or nitrogen, in the case of ammonia), synthetic fuels offer a major advantage: they are compatible with existing engines, infrastructure and logistics.

These are drop-in solutions, allowing decarbonization without the need to rebuild entire fleets, ports or fuelling networks from scratch.

Synthetic fuels are part of a broader family of low-carbon alternatives, including advanced biofuels. Biofuels are already commercially deployed, yet their scalability is limited by land use, feedstock availability and sustainability concerns. Synthetic fuels, by contrast, are more scalable in principle but rely on abundant renewable electricity and a steady, cost-effective supply of captured CO₂.

At present, synthetic fuels are still in the early stages of market development. Production volumes remain low, and costs are significantly higher than fossil counterparts - typically seven to nine times more.

RFNBOs are Renewable Fuels of Non-Biological Origin, such as green hydrogen, produced exclusively from renewable energy sources (wind, solar, hydro) and not from biomass. They will play a key role in decarbonizing industrial and transport sectors, especially those that are hard to electrify, like aviation and maritime shipping.

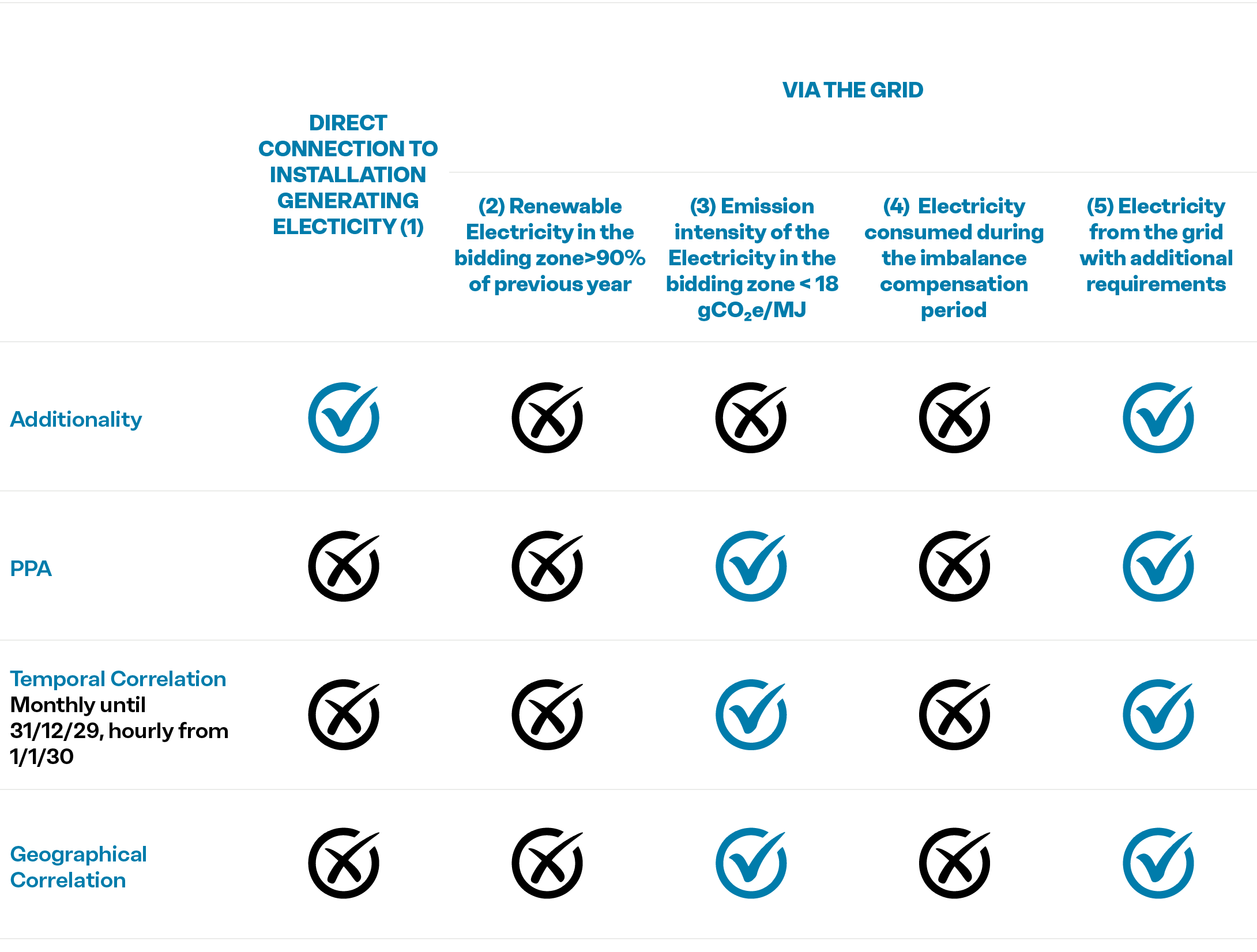

Renewable energy can be taken from a direct connection to a renewable electricity installation, in the same installation of the RFNBO producer (direct connection), or from the grid (grid connection).

RFNBO certification is governed by the Renewable Energy Directive and two EU Delegated Regulations.

The main requirements for the RFNBO certification are:

* If a RFNBO plant comes into operation before 1 January 2028, the RFNBO plant is exempted until 1 January 2038

Why certification matters:

Carbon Capture and Storage (CCS) will be of paramount importance if we are to reach net zero targets. For emissions that are unavoidable, it will be essential to sequester the CO₂ from the process that produces it and safely store it in proper underground reservoirs.

The pipeline that transports the CO₂ from the site of production and sequestration to the geological reservoir is a key element in the success of the system.

The pipeline transportation of CO₂ faces several technological challenges. In addition to corrosion problems, controlling propagating fractures along the pipeline remains the next most pressing issue. An accidentally generated crack on a pipeline can propagate along the line for distances of up to several hundreds of kilometres without any arrest, sustained by the intrinsic energy of the conveyed high-pressure gas.

This issue has been successfully resolved for traditional natural gas transportation. Thanks to a wide set of full-scale experiments, it has been possible to establish design rules to control the phenomenon in new pipelines.

A series of tests carried out over the years at RINA’s test station in Perdasdefogu, Sardegna, made a significant contribution to these findings.

Notwithstanding, CO₂ transportation represents a further challenge. CO₂ is in fact transported in dense phase that, during decompression following an accidental leakage, undergoes a phase transition (i.e. dense to gaseous phase).

This corresponds to an additional, important driving force as the expanding gas, during phase transformation, does not reduce in pressure even while expanding its volume.

The world of yachting is embracing a new era with a different generation of owners and clients who expect innovation, digital solutions and, above all, care for the environment.

Already we have seen series of new yachts using hybrid propulsion and biofuels, and even yachts fuelled by green methanol and green hydrogen.

Among the potential new technologies, nuclear is also gaining traction mainly due to a new generation of reactors and a general consensus among various institutions that it represents a promising viable long-term solution.

Among the Generation IV nuclear reactors, several will soon reach a milestone of testing safety and performance in non-fissile conditions. This in turn will generate a wealth of information that can be used to build prototypes, leading to the first marine installations and commissioning. Indeed, the existing nuclear technology used for naval ships and icebreakers has a positive track record in terms of safety and operational life.

Generation IV nuclear reactors are intrinsically safe by design, and combined with SMR (Small Modular Reactors) technology are defined as AMR (Advanced Modular Reactors). Safety is assured with passive cooling systems and minimal operator intervention.

Additionally, a hybrid approach combining nuclear power with renewables, battery storage and electrical propulsion will further optimize efficiency and safety.

The development of more compact small reactors, suitable for middle size yachts, is expected to reduce installation costs over the longer term and enable a more efficient internal space design.

Resilience to natural and climatic hazards has become essential, and must now be included in our vision for a sustainable and liveable future.

Some 80% of cities around the world have reported significant natural and climatic hazards since 2022, while extreme weather events in Italy have nearly quadrupled over the past decade. Whilst the financial resources available for climate adaptation vary according to political willingness, it is estimated that only 3% of extra investment worldwide would be needed to create global climate resilience.

To enable evidence-based decisions, and to provide viable and sustainable solutions to build climate resilience in the built environment, the MULTICLIMACT project (https://multiclimact.eu/) was launched in October 2023. The project aims to safeguard Europe’s built environment against the rising threats of natural and climatic hazards.

MULTICLIMACT supports citizens and local authorities in understanding, improving awareness and measuring the resilience of the built environment, its assets and services delivered.

In doing so, MULTICLIMACT aims to proactively and efficiently tackle some of the increasing natural and climatic risks. These include urban and river floods, landslides, urban heat waves and heat islands.