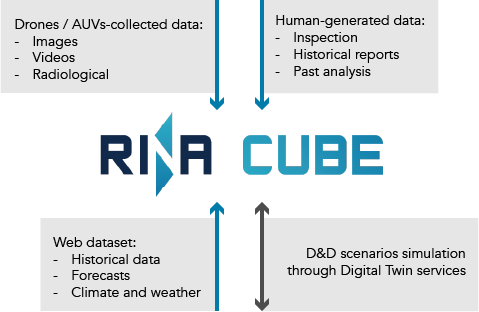

The concept

of a “digital twin” is fairly recent. Moreover, its application in the nuclear

power sector is new, and brings additional challenges due to the dynamic nature

and significant uncertainty of the nuclear process.

A digital

twin is a digital representation of an intended or actual real-world physical

product, system, or process that can be used for practical purposes such as

simulation, integration, testing, and monitoring. It has been recognized that

digitalization across the life cycle of the nuclear industry could deliver

significant advantages, providing improved process reliability, which would reduce

scheduling and cost risk while ensuring operations are undertaken safely.

The digital

twin includes the use of numerical models that cover the operation of the

asset. These models can simulate scheduled operations and the process flows of

waste material, extending down to chemical models that can account for changes

in speciation and solubility as a function of process conditions. Statistical

tools, developed to calculate the uncertainty in plant data, can also be incorporated

into predictions.

The Cleandem project,

funded by HORIZON 2020 programme, is currently studying digital twin

applications for nuclear decommissioning activities. Data from drones and other

specific tools would be plugged into the digital twin in order to model the

dynamics of the system, from starting stage to fully decommissioned state.

The strategy adopted is typically to

undertake early phase operations in a cautious manner (leading phase) in order to

gather information during early retrievals (learning phase). This knowledge

allows acceleration of the decommissioning in later phases. The digitalization

of the information manager has the potential to extract as much useful

information as possible from retrievals to improve predictions of how to

operate in later years.

It can also

be important to consider additional variability due to the availability of

resources and failure (e.g. mechanical) of plant equipment. We can add to this

complexity the dynamic changes in the system chemistry which in turn impacts on

our ability to treat the effluent. All of these processes require different

types of models and the usual practice is to develop independent models in

software specifically and optimally designed for the purpose of solving a

particular type of real-world problem.

The adoption

of a digital twin provides a simple, easy-to-use interface that can be accessed

by any interested party through the use of the models. In this way, it can also

increase the number of stakeholders who can participate in improving a system’s

overall process reliability.

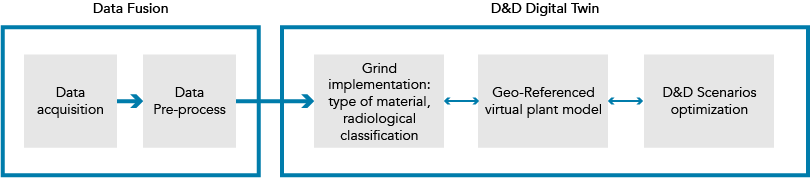

Ships’

diesel engines contribute around 80% of the total carbon emissions produced in

ports, impacting both the port area and the local surroundings.

In order to

reduce these emissions, Onshore Power Supply (OPS) is set to form a key part of

the energy transition, offering one of the best ways to decarbonize shipping

activity while in port.

The main

benefit of OPS, also known as ‘cold ironing’, is to enable vessels to shut down

their auxiliary engines at berth while still maintaining onboard services.

This

alternative energy solution offers a crucial method of lowering carbon

emissions. Furthermore, OPS eliminates the vibrations and noise pollution from

ships’ engines, improving the quality of life in the areas surrounding the port.

However, several

factors currently limit the full deployment of OPS in ports.

Firstly, in

order to be economically viable, shore-side electricity supply needs to be more

cost competitive than the ship’s own fuel consumption. As a consequence, appropriate

incentive programmes should be created to encourage ship owners to invest in

the onboard systems needed to plug into onshore power sources.

Moreover,

significant investment is required in OPS berths in terms of facilities,

infrastructure, technologies and equipment. Public funding will be a key factor

in promoting OPS installation in all shipping sectors.

There is

currently no international legislative framework in place to mandate or

facilitate the use of OPS in ports worldwide.

However, significant

progress has been made in Europe in the form of Directive 2014/94/EU, which

establishes a common framework of measures for European Union Member States to use

alternative fuel infrastructures.

According

to the Directive, OPS shall be installed as a priority in EU maritime and

inland ports by the end of 2025, provided the economic and environmental

benefits are consistent. This will provide a further incentive for shipowners.

Due to the

variety of factors that can potentially hamper OPS investments, an integrated

approach across the different disciplines has proven to be the best route

towards successful project development.

Such an

integrated approach needs to include a comprehensive feasibility study to

evaluate the viability of the investment prior to the implementation of any OPS

project.

Several

aspects need be taken into account based on the port location, readily available

power supply, and berthing capacity.

These

include: identification of the best technical solution to fit the purpose of

the specific port and terminal, estimation of all project-associated costs,

revenue calculations, legal implications, assessment of environmental, social and

economic benefits to the community, as well as to the industrial and commercial

sectors of the territory.

The success

of OPS projects also relies on the involvement of ship owners in the

decision-making process, in order to foster more investment in onboard OPS

technology.

Today,

we are seeing an increasing number of initiatives being developed in the transition

to full decarbonization. Within this framework, hydrogen represents a key pillar

of the energy transition necessary to limit global warming to 2 Celsius degrees

and to achieve net zero emissions by 2050.

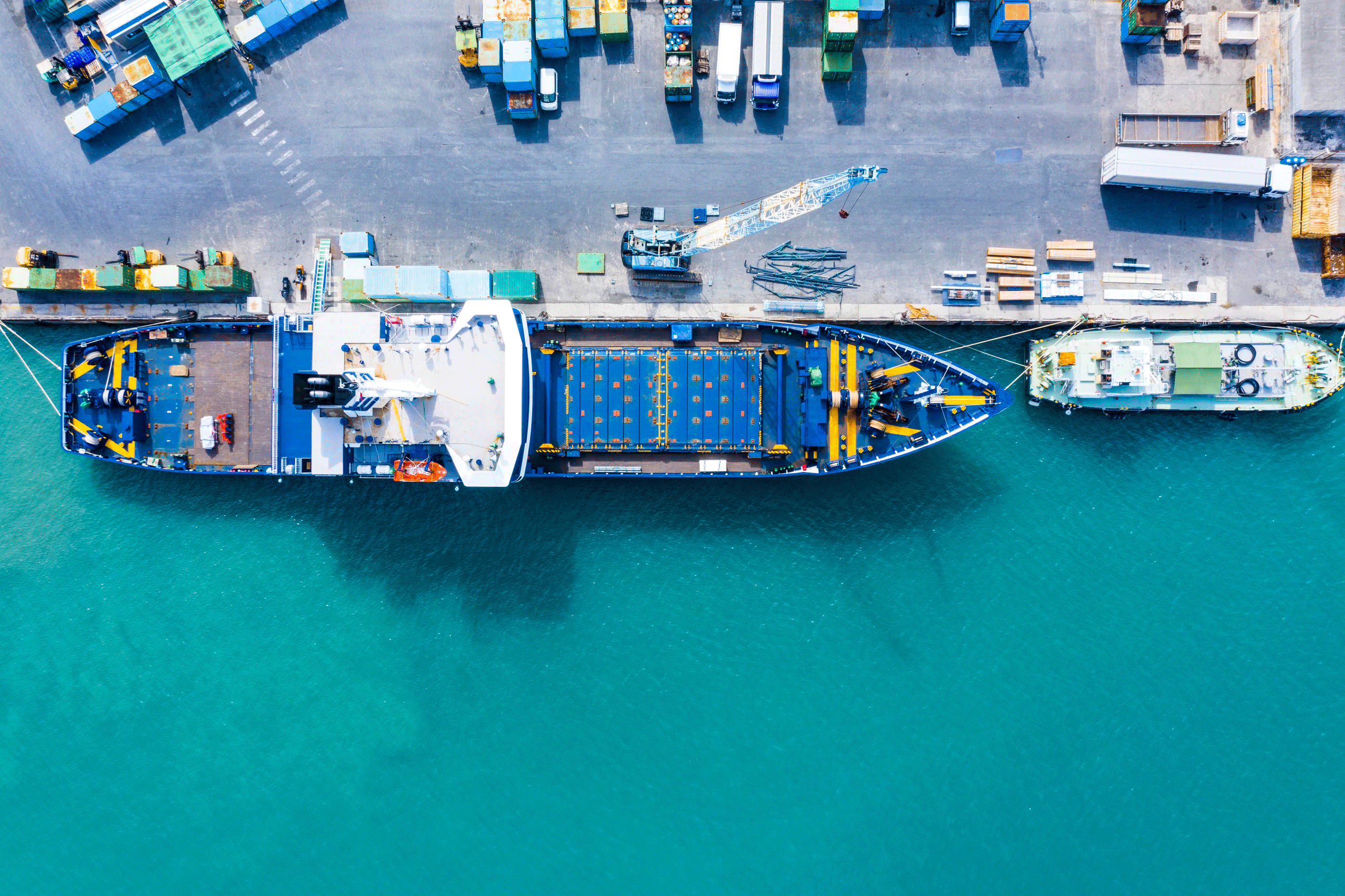

The

energy sector, with its focus on transmission and distribution networks, is now

being asked to deliver significant volumes of hydrogen from production sites to

end users.

Where

feasible, the exploitation of existing pipelines through life extension and

conversion from natural gas to hydrogen service (i.e., repurposing or

retrofitting) is the first option to consider. However, this is not always technically

possible or economically viable, and the realization of new “hydrogen-ready”

pipelines has become mandatory.

Despite

this, the regulatory framework relevant to hydrogen service and hydrogen

applications is still incomplete.

RINA

is working hard to fill the regulatory gap, and is now presenting two “H2-Ready

Method Statements”.

The

first helps carbon steel line pipe manufacturers certify and deliver ready

made products for hydrogen transmission and distribution networks.

With

this Method Statement, a specific line pipe production can be declared compliant

with the highest H2 usage factor (up to 72%) according to the applicable

principles of Option B (Performance-Based Design Method) of ASME B31.12:2019 “Hydrogen

Piping and Pipelines”.

The

Method Statement covers applications and limitations, as well as a series of

requirements such as material traceability, manufacturing route, steel grade,

chemistry, toughness, mechanical properties, welding and hydrotest. This

enables manufactured carbon steel line pipes to be certified H2-ready.

The

second Method Statement developed by RINA applies to metallic valve types intended for the

construction of gas transmission and distribution

pipelines, and hydrogen piping systems. It covers the requirements relating to

all the valve’s components (metallic and non-metallic) at different functions

and working at different stress levels, and assists metallic valve

manufacturers in the qualification of their H2-ready products.

Several

requirements, such as applications and limitations, material requirements,

design criteria for unlisted valves, and functional requirements, are specified

in this Method Statement in order to obtain the qualification of a H2-ready

metallic valve.

Once

the above requirements are satisfied, an official statement is issued by RINA declaring

the given line pipe/valve production inspected, verified, and H2-ready

according to the relevant Method Statement.

In

this way, RINA is helping to fill the regulatory gap, enabling industry to keep

pace with the rapidly evolving demands of decarbonisation and the energy

transition.

"H2iseO

Hydrogen Valley" is an Italian hydrogen-based industrial value chain for a

sustainable mobility system in Val Camonica, a UNESCO World Heritage Site,

along the non-electrified Brescia-Iseo-Edolo railway line.

The project has

three phases:

- The first phase involves the arrival of

the first 6 hydrogen-powered electric trains, which will be built by Alstom and

delivered by 2023. Between 2021 and 2023, a first hydrogen production plant

will also be built at Iseo station

- In the second phase, another 8 hydrogen

powered trains will be delivered, thus completing the replacement of the entire

fleet with totally green vehicles. In addition, one or possibly two further

hydrogen production plants are planned for the Brescia and/or Edolo areas by

2025

- In the third phase, the hydrogen

produced by the plants can be used for vehicles other than trains, starting

with public transport and the 40 buses managed in Val Camonica by FNM

Autoservizi

RINA is proudly to

be working on this project delivering design consultancy services for several of

the hydrogen production, storage, and distribution sites. As an environmental

engineer, I firmly believe that this is a groundbreaking project, contributing

to the achievement of the “first of its kind” system in Italy.

Once

realized it will be a case study that should guide and assist the development

of similar projects, significantly contributing to an historic change in the

mobility sector. While there are challenges every day, it is a credit to the

team behind the project who have made it possible with their strategic vision

and strong personal commitment.

The

decarbonization process is “The Challenge” of our generation. I strongly

believe that the achievement of our decarbonization goals depends first on a behavioural shift and

we all need to contribute with a personal

commitment to change.

The

"hydrogenisation" of the Brescia-Iseo-Edolo railway line as the first

to use hydrogen means that hydrogen production and distribution infrastructures

can be set up in the area to support the local economic and industrial sector.

In this sense,

the "H2iseO Hydrogen Valley" will not only decarbonize a railway line

but also encourage the development of an economic and industrial district based

on hydrogen in the area, thus contributing to the cultural change.

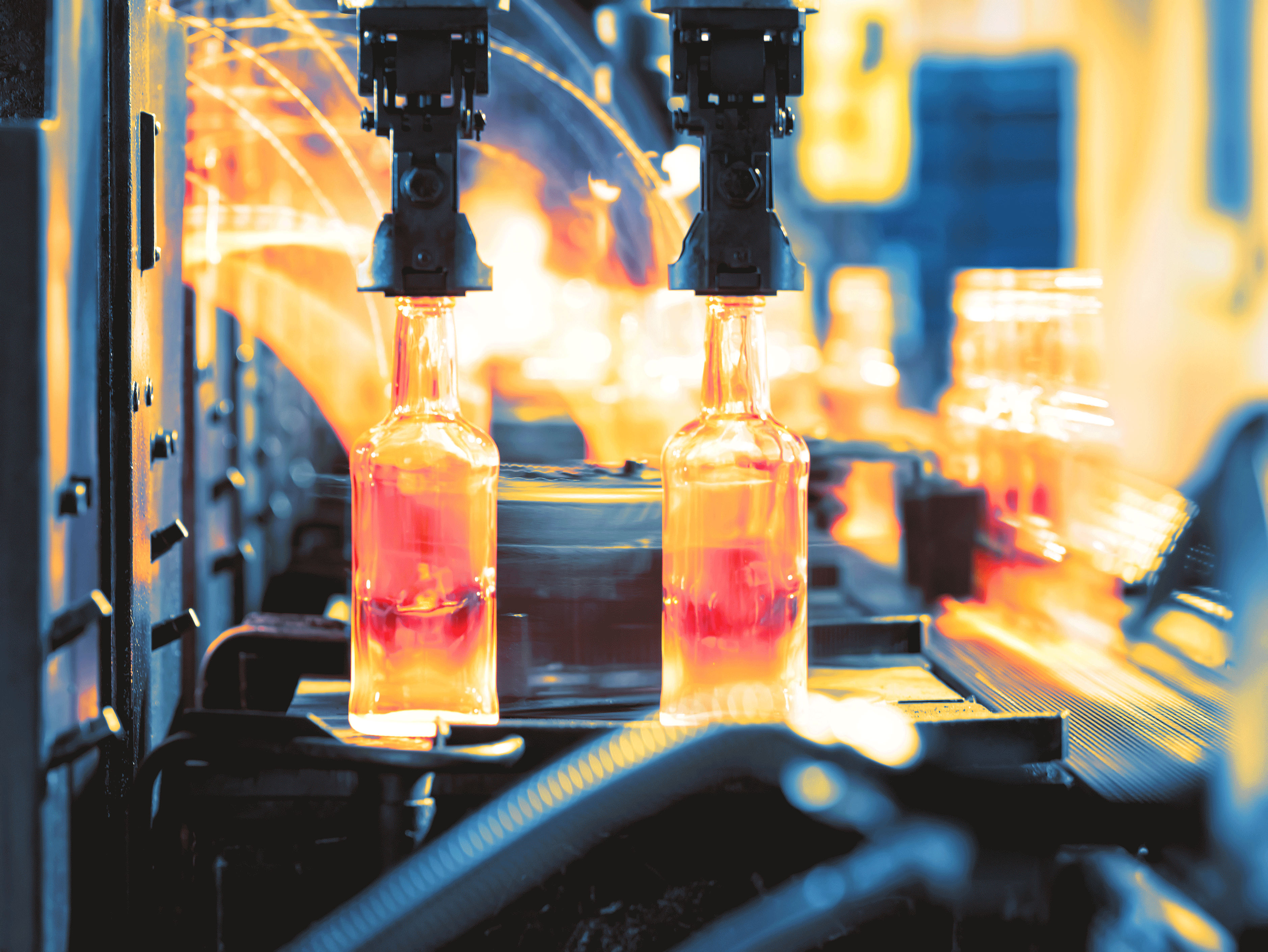

RINA is active

in the hard-to-abate sector, in particular in supporting companies develop

innovative combustion systems to lower their CO2 emissions. Green hydrogen can

be a viable substitute for natural gas, initially by blending it, and in the

longer term by potentially replacing it altogether.

RINA is

supporting the steel and glassworks sector, using its expertise in hydrogen

combustion to develop projects to decarbonise melting processes. The goal is to obtain a

full-scale pilot

capable of demonstrating the technology of production by hydrogen combustion.

The challenges

that have to be met are of a different nature, from the heat input aspects that

have to be guaranteed to the NOx emission aspects that have to be controlled by

tuning the combustion optimally to demonstrate that the properties of the

resulting glass are equivalent to the traditional method.

At present, we

are at the stage where we have identified a technological pathway that can be

followed but which must be supported by dedicated funding in order to be able

to incorporate the fast-changing technology.

Glass melting furnaces use energy from

natural gas combustion, so can potentially be converted to use hydrogen as an

alternative fuel. Hydrogen combustion has several differences compared to

natural gas combustion, with potential impacts on the thermodynamics and

kinetics of the glass production process, as well as on the furnace and the

combustion systems industrially adopted.

The strategy adopted is typically to

undertake early phase operations in a cautious manner (leading phase) in order to

gather information during early retrievals (learning phase). This knowledge

allows acceleration of the decommissioning in later phases. The digitalization

of the information manager has the potential to extract as much useful

information as possible from retrievals to improve predictions of how to

operate in later years.

It can also

be important to consider additional variability due to the availability of

resources and failure (e.g. mechanical) of plant equipment. We can add to this

complexity the dynamic changes in the system chemistry which in turn impacts on

our ability to treat the effluent. All of these processes require different

types of models and the usual practice is to develop independent models in

software specifically and optimally designed for the purpose of solving a

particular type of real-world problem.

The adoption

of a digital twin provides a simple, easy-to-use interface that can be accessed

by any interested party through the use of the models. In this way, it can also

increase the number of stakeholders who can participate in improving a system’s

overall process reliability.

¹ The project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking (now Clean Hydrogen Partnership) under Grant Agreement No 779606. This Joint Undertaking receives support from the European Union’s Horizon 2020 Research and Innovation program, Hydrogen Europe and Hydrogen Europe Research.”

A solar fuel is a synthetic chemical fuel, like

hydrogen, methanol or methane, which is produced from a common substance like water

or carbon dioxide by applying solar energy.

The production of solar fuels complements power

generation from photovoltaic and other types of solar power plants, and is set

to play an important role in the challenge to exploit the sun’s huge potential

energy.

Indeed, according to the US Department of

Energy, the amount of solar energy striking the earth's surface in one hour

(170 PWh) is enough to support the world's energy consumption for an entire

year (160 PWh).

Solar fuels have two principal advantages: they

address complementary sectors and final uses, including “hard to abate” sectors

that are difficult to electrify; and they allow the adoption of different

storage technologies, thus increasing the flexibility of the energy system in response

to fluctuating energy needs.

Moreover, solar fuels have the potential to replace

current fossil fuels, thus reducing GHG and pollutant emissions, and thus contributing

to the transition to renewables and the diversification of our energy supply.

For these reasons, the production pathways for solar fuels are increasingly being

studied at EU and international level.

The production of solar fuels can be carried

out through different technological pathways including electrochemical,

chemical, thermochemical and biochemical processes. Within these pathways, the

most viable solution is currently hydrogen production through water electrolysis

with electricity from solar PV.

However, there are other promising technologies

for the future including photoelectrochemical cells (combining both stages in a

single device producing hydrogen directly from solar energy), and CO2

hydrogenation, producing methanol from green hydrogen and carbon dioxide

captured from the air or coming from a CCS plant.

The market for solar fuels is currently at an

early development stage, but its potential to meet worldwide energy needs has

been estimated at 4%-6% by 2050 and 6%-10% by 2100.

Besides the technological challenges, the main driver

to achieving these targets will be economic: on the one hand, the carbon

emissions price is expected to increase in future, while on the other hand solar

electricity costs are expected to decrease. The market outlook for solar fuels

should therefore become favorable in the coming decades.

RINA has an increasingly high level of

expertise in this field. The company provided technical assistance to the

European Commission in 2014-2015 on “Algae Bioenergy Siting, Commercial

Deployment and Development” (together with Padova University and SELC), and in

2019-2020 on “Solar Fuels Research & Invest” (with EY, IMEC and CEPS).

Moreover, RINA has been involved since 2021 in

the Spotlight project (“Sunlight Production of Chemical Fuels”), led by TNO and

co-funded by the European Commission under Horizon 2020.

The aim of the project is to develop and

validate a photonic device and chemical process concept for the

sunlight-powered conversion of CO2 and green H2 to

methane and methanol, which is fully compatible with our current infrastructure

and suitable for multiple applications.

¹GLOBAL OFFSHORE

WIND REPORT 2020. Global Wind Energy Council. Available online: https://gwec.net/global-offshore-wind-report-2020/

²IRENA–International Renewable Energy

Agency. Available online: https://www.irena.org/ (accessed on 20 July 2020).

Biofuels are set to play a key role in the

fight to reduce carbon emissions. Potentially applicable in both the transport

and energy sectors, this relatively new form of energy is derived from a range

of different oils including vegetable oil, animal fat, waste oil, microbial oil,

and waste cooking oil.

As the world’s most populous country, China

is a major generator of waste cooking oil. Today, the country’s waste oil

supply is around 3 million tons per year, with a potential to rise to 10

million tons annually.

China’s biofuel is mainly exported to the

European Union, which today consumes 40% of all worldwide biodiesel supplies. Trade

between the two partners is expected to grow further following the introduction

of the new EU Renewable Energy Directive RED II. Under the directive, EU

members will move to generating 32% of their energy from renewables by 2030,

with a possible uplift in this percentage to be decided this year.

As a result, Chinese biofuel exports to the

EU have the potential to more than triple by 2030 compared to the 2 million

tons recorded in 2021, an effective compound growth rate of 14.3% per year.

RINA is today one of the leading

certification bodies for biofuel in China, issuing several hundred biofuel

certificates each year. The first ever biofuel certificate in the country, as

well as the first sustainable aviation fuel certificate, were both issued by

RINA.

By offering high levels of professional

service to producers, backed by broad experience, RINA is helping Europe move

towards a more sustainable era.

The journey towards decarbonization is a

complex one where multiple solutions and technologies will play a role. All

will contribute to achieving the goal of zero emission on a global scale across

the sectors.

Carbon capture is indeed a critical part of the

portfolio of technologies for sustainability particularly in relation to industrial

emissions. Carbon capture technologies find their applications in specific point

sources where concentrated emissions occur. It

is not an economical and technical viable solution for the widespread emission

point as per the land mobility sector case.

Removing carbon dioxide can support the transition

towards cleaner energy vectors but can also support the decarbonization of CO2

coming from industrial processes: indeed, carbon capture means preventing emissions

from entering the atmosphere after they have been produced, either as a product

of a combustion or as byproduct of a specific industrial process.

Which industry?

In the first case, carbon capture must be seen

as a transition measure towards the adoption of cleaner energy vectors.

In the other cases, CO2 production is a direct

and unavoidable consequence of the industrial process. For example, in the cement

industry, where 50% of the CO2 produced from the manufacturing process comes

from the decarbonation reactions of calcium carbonate - the reaction underlying

the cement production process itself, carbon capture is probably the most

effective solution to deploy.

The use of carbon capture in industrial

processes dates backs to the 1930s, when chemical solvents were used to absorb

CO2 in the natural gas industry in order to obtain pure methane. Later, physical

solvents were used in gasification plants using coal, petroleum coke, and

biomass feedstocks. In the middle 20th century, adsorption processes

using solid sorbents enabled the gas separation in hydrogen production in refineries

and nitrogen production.

Modern methods of carbon capture

In recent years, membranes have been developed

to capture CO2. Today carbon capture technologies are usually categorized as

follows: post-combustion, pre-combustion and oxy fuel combustion.

Post-combustion technologies are applied to

exhaust gases and do not require significant changes in the original process:

gases are first treated to remove particulate matter and the oxides are then

put in contact with solvents, typically an aqueous amine solution, to absorb

the CO2 and enable nitrogen and oxygen to be released into the atmosphere.

Pre-combustion refers to removing CO2 from

fossil fuels before combustion is completed, while oxy fuel combustion is the

process of burning a fuel using pure oxygen instead of air, producing

approximately 75% less flue gas than air fueled combustion and exhaust

consisting primarily of CO2 and H2O.

Of course, the selection of the most

appropriate technology must be done according to the characteristics of the

flue gases in terms of temperature, pressure, CO2 content and flow, but also

considering how it modifies the industrial process.

Nowadays, CO2 is a commodity, with more than 200

million tonnes (Mt) of CO2 used every year globally, mainly in the fertilizer industry

(for manufacturing processes) and the Oil & Gas industries (for reservoir

enhancement).

All elements of the

carbon capture and storage value

chain are mature and have been in commercial operation for decades, but incremental

improvements to carbon capture technologies will continue to reduce cost and improve

performance - especially in low-concentration dilute gas streams. However, transport

infrastructures will need to scale up to increase the quantities of removed CO2

and its segregation or further reuse, while tackling the issue of international

logistics.

Groundbreaking infrastructure projects

RINA has been recently involved in studies and

assessments to repurpose pipelines originally designed for the export of

hydrocarbons from operating reservoirs which will soon be reemployed to inject

CO2 in depleted wells in UK. Similarly, RINA is working on Approval in

Principle of the conversion of two existing gas pipelines in Italy with the

final objective to certify the fitness for service in the new operating

condition.

New challenges will come soon from terminals,

where assets originally designed for LNG could be soon converted to handle CO2:

the compatibility of existing equipment must be assessed, and our laboratory

assets are fully equipped for conducting tests - up to full scale including offshore

burst test - in pure CO2 environments or in the presence of other contaminants.

Fracture initiation-propagation, corrosion, internal coating behavior and

leakage are all areas of investigations in which RINA has longstanding

expertise and experience.

Moving to sea and air

Furthermore, new technological breakthroughs will

soon enable carbon capture to be deployed in new applications beyond industry:

examples include direct air capture (DAC) and CO2 capture from seawater.

Capturing CO2 from the air requires overcoming

technical - and consequently economic challenges - due to the much greater

dilution of carbon dioxide compared to an industrial point source.

Meanwhile, oceans - with a CO2 concentration

100 times greater than air - are responsible for soaking up some 30% of

humanity's total annual carbon emissions resulting in the ecosystem's degradation

due to ongoing acidification processes and the depletion of oxygen content.

In the forthcoming scenario, the CO2 value

chain could play a key role in decarbonization, bringing together industries,

dedicated transport assets - via ships and via pipe - final segregation sites

or new end users.